When you pick between manual and automated wire soldering machines, you will see big differences in price, speed, and needed skills. Manual machines need skilled workers, so labor costs go up. Automated wire soldering machines help you save money and work faster, especially if you make a lot of products. Many industries now like automated machines because they are more accurate and give better quality. If you also use wire crimping machines or cutting and stripping solutions, automation can make your whole process easier. Always think about your project size, budget, and worker skills before you choose.

Manual soldering machines let you control the work. They are best for small jobs, repairs, and careful tasks. Automated soldering machines work faster. They help make better products and save money on big jobs. You should pick a machine based on your project size, budget, and team skills. Automated machines cost more at first and need training. But they give steady results and make more products. Using wire crimping and stripping machines with soldering tools helps you work faster and easier.

Manual Wire Soldering Machines

![Manual Wire Soldering Machines]()

Manual Soldering Pros

Manual wire soldering machines have many good points. You get to control the process yourself. You can change your method for each project. This is helpful for tricky or delicate work. Manual crimping is good for small jobs or custom work.

Manual wire soldering machines have been used for a long time in electronics assembly, repair, and making new designs.

You can use manual soldering for tiny jobs, like working with flexible or heat-sensitive materials.

New manual machines have digital temperature controls and are easier to hold, so your work is safer and more exact.

Manual crimping is still needed in fields like car electronics and medical devices, where you must be very accurate.

More people are doing DIY electronics and hobby projects, so there are easy-to-use manual tools for homes or small businesses.

Tip: Manual soldering wires can make joints that are almost free of gaps and very strong. You can get up to 39.6 N shear strength on normal parts, which is as good as or better than other ways of joining.

Aspect | Description / Value |

Shear strength (standard parts) | Up to 39.6 N with preheating |

Flexibility | Works on flexible PET foil and polyester textile substrates |

Joint quality | Nearly void-free, strong, and reliable |

Process adaptability | Handles various component sizes and solder alloys |

Manual crimping works well with new soldering materials and rules for the environment. You can use lead-free solder and new methods to make things safer and more reliable.

Manual Soldering Cons

Manual wire soldering machines also have some downsides. Manual crimping takes more time and effort than using machines. You need skilled workers to get the same results every time. It can take a long time and cost more to train new workers.

Manual soldering can make workers tired, especially if they work long hours.

You might see more changes in joint quality if workers do not follow the right steps.

Manual crimping is not as fast for making lots of products, so it can slow you down.

Manual soldering wires may not be quick enough for big factories.

Note: Manual soldering machines need regular care and careful use to keep working well. If you need to solder thousands of wires every day, manual crimping may not be the best choice.

Manual wire soldering machines are still good for small jobs, repairs, and special projects. But if you need to make a lot of things, you might want to use automatic machines or mix manual soldering with wire cutting and stripping machines or terminal crimping machines to work faster.

Automated Wire Soldering Machines

![Automated Wire Soldering Machines]()

Automated Soldering Pros

Automated wire soldering machines have many good points for factories. These machines make work faster and more accurate with automated crimping. They do the same job over and over without getting tired or making mistakes. You get the same soldering quality every time, which is important for electronics and aerospace.

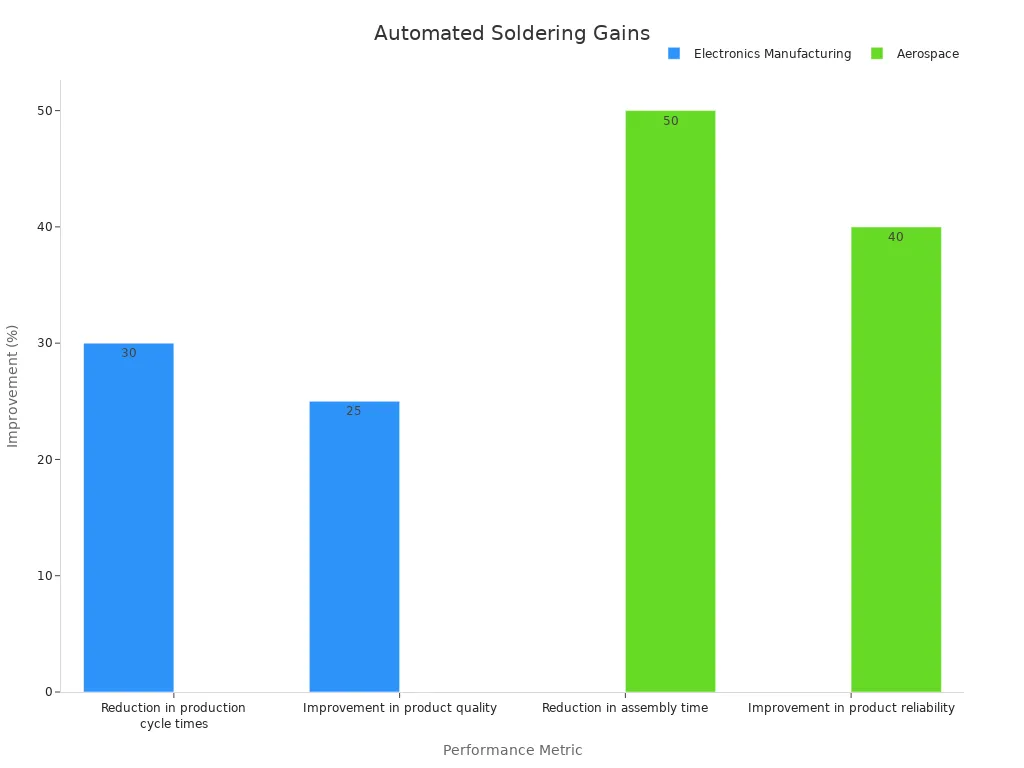

You will notice your process gets better. Automated crimping helps you finish jobs faster and makes products better. The table below shows how different industries get better results with automated wire soldering machines:

Industry Sector | Performance Improvement Metric | Improvement Figure |

Electronics Manufacturing | Reduction in production cycle times | 30% |

Electronics Manufacturing | Improvement in product quality | 25% |

Aerospace | Reduction in assembly time | 50% |

Aerospace | Improvement in product reliability | 40% |

![Bar chart comparing performance improvements by industry sector using automated wire soldering machines]()

Automated crimping also helps you work better by using things like ultrasonic cleaning. This keeps the soldering nozzles clean, so you have less downtime and the nozzles last longer. You spend less time fixing machines and more time making things. These machines use precision control and watch the process all the time, so you can make more products and earn more money. If you use automatic crimpers or wire cutting and stripping machines, you can make your work go faster and smoother.

Tip: Automated wire soldering machines work well with wire harness assembly solutions and other automated crimping tools. You can make more products without losing quality.

Automated Soldering Cons

Automated wire soldering machines also have some bad points to think about. You need a lot of money at first to buy and set up these machines. Automated crimping systems often need skilled workers to run and fix them. Training your team can take time and cost money.

Studies show that automated soldering systems can be hard to use. You might have problems like not enough skilled workers and strict rules. Reports say these machines can cost a lot to run and fix. Technology changes fast, so some machines can become old quickly. Problems with getting parts can also slow down your work if you use automated crimping.

Note: Automated wire soldering machines have many good points, but you need to plan for the costs and skills to keep them working well.

If you work in automotive, electronics, or new energy, automated crimping and wire soldering machines can help you make more products. Always think about the good and bad points before you decide.

Manual vs Automated Soldering Comparison

Soldering Quality

You want your solder joints to be strong and last long. Manual soldering lets you control each connection by hand. You can change how you work for special or fragile parts. This is good for fixing things or making custom items. But, the results can change if workers have different skills.

Automated soldering machines use smart technology to make every joint the same. These machines keep heat and timing steady. This means fewer mistakes and very exact work. Automated crimping helps keep things even more stable. Many companies, like car and electronics makers, use these machines to meet tough quality rules. Selective soldering systems can cut mistakes by half. That is why they are great for hard jobs.

Tip: If you always need top quality, automated soldering machines are the best pick.

Efficiency and Speed

You need to finish work fast, especially with big orders. Manual soldering is quick and easy for small jobs or repairs. You do not have to set up machines, so you can start right away. This saves time for test projects or one-time fixes.

Automated soldering machines can make twice as many products as manual work. These machines do not need breaks and do not slow down. You can keep making things all day. Automated machines also cut labor and training costs by half. The table below shows how both ways compare:

Aspect | Automated Soldering (Weller WTBR 1000) | Manual Soldering |

Output Speed | Typically allows for twice as much output compared to manual | Lower output, inconsistent due to human factors |

Production Continuity | Continuous production avoiding bottlenecks | Subject to delays and bottlenecks |

Cost Efficiency | Up to 50% reduction in labor and training costs | Higher labor and training costs |

Quality Consistency | High precision with latest technology, consistent and repeatable | Variable quality depending on operator skill |

Suitability | High-volume production, continuous and versatile | Small batches, prototyping, repairs |

Time Efficiency | Avoids delays inherent in manual processes, increases productivity | More time-efficient for small runs due to no setup |

You can see that automated soldering machines help you finish big jobs faster and with less effort.

Cost Factors

You need to think about your budget when picking a machine. Manual soldering costs less to start. You only need simple tools and some training. This makes it a good choice for small shops or repair work.

Automated soldering machines cost more at first. You have to buy the machine and teach your team. But, you save money later because you need fewer workers and make fewer mistakes. Industry numbers show automated machines can cut labor costs by over 30%. If you make lots of products, you save more money over time.

Note: For making many products, automated machines save more money in the end.

Application Suitability

You should pick your soldering method based on your project. Manual soldering is best for small jobs, repairs, and custom work. You can change how you work for each task. Manual crimping is also good for delicate jobs or fixing just one part.

Automated soldering machines are best for making lots of products. They are used in electronics, cars, and factories. These machines handle hard jobs quickly and accurately. Automated machines also meet strict safety and quality rules. Many companies use them to follow green rules like RoHS.

You can also use automated soldering with wire cutting and stripping machines for a full setup. This helps you finish big orders easily.

Applications like telecom, new energy, and aerospace often need the speed and accuracy of automated machines. Manual ways are still important for test projects and repairs.

Manual vs Automated Soldering: Side-by-Side Comparison

Feature | Manual Soldering | Automated Soldering |

Flexibility | High | Moderate |

Speed | Low to Moderate | High |

Cost (Initial) | Low | High |

Cost (Long-Term) | Higher (labor) | Lower (per unit) |

Quality Consistency | Variable | High |

Skill Requirements | High | Moderate (after training) |

Scalability | Limited | Excellent |

Best For | Small batches, repairs | High-volume production |

Setup Time | Minimal | Required |

Adaptability | Excellent | Good |

Suzhou Crown Electronic Technology Co., Ltd. has both manual and automated wire soldering machines. You can find machines for any industry, from cars to new energy. Suzhou Crown also sells wire crimping machines, wire cutting and stripping machines, and other wire tools. You get expert help, training, and service to help you pick the right machine for your needs.

Choosing a Soldering Machine

Project Size

First, look at how big your project is. If you have small batches or custom jobs, manual wire soldering machines give you more control. You can change how you work for each job. For big projects, automated wire soldering machines help you finish faster. In the automotive industry, automatic selective soldering systems can cut soldering time by 40%. They can also boost output by 20%. This makes automation a smart pick for making lots of products.

Budget

Your budget is very important when you choose. Manual soldering machines cost less at the start. You spend less on tools and training. Automated machines cost more at first, but they save money later. They do this by lowering labor costs and making fewer mistakes. Many companies see that automated systems pay for themselves with big jobs. You should also think about the price of other machines, like wire crimping machines and wire cutting and stripping machines. These can help your work go smoother.

Skill Level

Think about how skilled your team is. Manual soldering needs workers who can make careful joints. Training takes time and effort. Automated machines use technology to keep quality high, even if your team is less skilled. You can use quality control tools like Statistical Process Control (SPC) and Automated Optical Inspection (AOI) to check your work. These tools help you keep your process steady and your products good.

Industry Needs

Every industry wants different things. If you work in electronics, automotive, or new energy, you may need to follow strict quality rules. Automated soldering machines help you meet these rules and keep your products the same. If you need to be flexible, like for repairs or prototypes, manual soldering is best. You should also find suppliers who give after-sales support, training, and custom help. Suzhou Crown gives installation help, maintenance training, and many wire processing machines to fit your needs.

Tip: Always see if your supplier gives technical support and training. This helps you use your soldering machine well and keeps your work running smoothly.

You now know the main good and bad points of manual and automated wire soldering machines. Manual machines let you have more control and change things as needed. Automated machines are faster and always do the job the same way. You should pick a machine that fits your project size, how much money you have, and your team's skills.

Quick Checklist for Choosing Your Soldering Machine:

Look at how many things you need to make.

Check how much money you can spend.

Think about what your team can do.

Remember to look at other tools like wire crimping machines or wire stripping machines.

For the best way to work with wires, ask experts or trusted suppliers for help. They can help you pick the right wire soldering machine for what you need.

FAQ

What is the main difference between manual and automatic wire soldering machines?

Manual wire soldering machines need you to do the work by hand. You control each step yourself. Automatic wire soldering machines use technology to do the job for you. These machines work faster and give the same results every time.

Can I use wire soldering machines for different wire types?

Yes, you can use wire soldering machines for many kinds of wires. You can also use wire cutting and stripping machines to get wires ready. Always check if your machine works with the wire size and material you have.

How do I choose between manual and automatic wire soldering machines?

Think about how big your project is, your budget, and your team's skills. Manual machines are good for small jobs or repairs. If you need to make a lot of things, automatic wire soldering machines and wire crimping machines save time and money.

Do automatic wire soldering machines need special training?

Yes, you need some training to use automatic wire soldering machines. Most companies, like Suzhou Crown, give training and help. You can learn how to use the machines with their support.

What other machines help with wire processing?

You can use wire crimping machines, wire cutting and stripping machines, and wire harness assembly machines. These tools help you finish your work faster and make your wire harnesses better.