When you use wire processing machines, you make the process of wiring a light switch faster and safer. These machines help you cut, strip, and connect wires with great accuracy. You can trust the results every time you install a switch. A wire harness tester checks your connections, so you know your switch works before you finish. Wire cutting and stripping machines save you time on each switch project. Reliable tools help you avoid mistakes and keep your switch installation up to code.

Wire processing machines cut, strip, and crimp wires fast. They help save time and lower mistakes.Always turn off the power before wiring. Wear the right safety gear to stop shocks and injuries.Pick the right machine for your project size and wire type. This helps you get neat and strong connections each time.Follow these steps: get wires ready, cut and strip them, crimp connectors, ground wires right, and test with a wire harness tester.Keep your machines clean and take care of them. This makes switch installations safe, quick, and reliable.

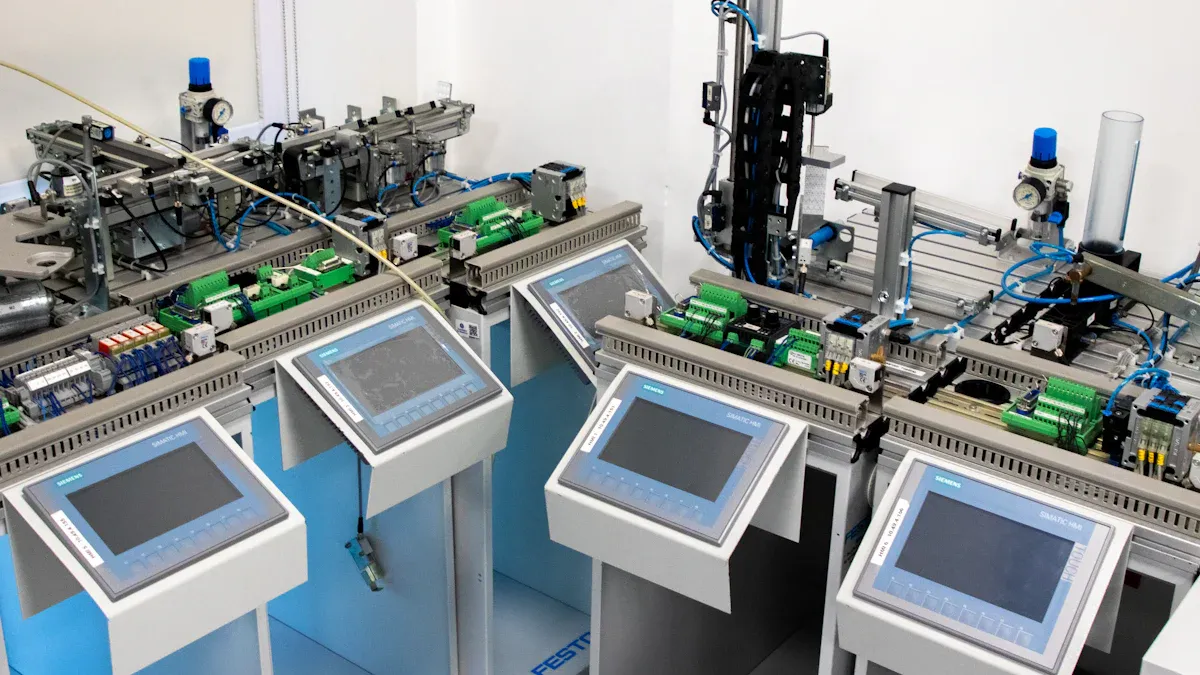

Wire Processing Machines

![Wire Processing Machines]()

Types of Machines

You need the right tools to wire a light switch. Wire processing machines help you work faster and safer. Here are some important types you might use:

Wire cutting and stripping machines: These machines cut wires to the right length. They also remove insulation in one step. This saves time and gives you neat results.

Crimping machines: You use these to put connectors or terminals on wire ends. This makes the connection strong and safe.

Wire harness tester: This device checks if your connections are correct and safe. You can find problems before you finish the job.

Automatic wire processing equipment: These machines do many steps at once. They can cut, strip, and crimp wires in one process.

Suzhou Crown has many machines for these jobs. Their machines are used in home wiring, cars, and electronics.

Key Features

Modern wire processing machines have features that make your job easier:

Cut and strip machines do two jobs at once. This means you do not have to handle wires as much.

You can set the machine for different wire types and sizes.

Automation helps you work faster and make fewer mistakes.

These machines can do lots of work quickly. They are good for small and big projects.

You can watch your work in real time and check data to keep quality high.

Tip: Using cutting and stripping machines with automatic settings makes every wire the same each time.

Choosing the Right Machine

Pick wire processing machines that fit your project. Think about the wire size and how many switches you need. Also, think about what connectors you will use. For small home jobs, a simple wire cutting and stripping machine is enough. For big jobs, automatic wire processing equipment saves you a lot of time. Suzhou Crown’s team can help you pick the best machine and show you how to use it.

Safety and Compliance

Power Off Procedures

Always turn off the power at the main breaker before you start. This keeps you safe from getting shocked. Use a voltage tester to make sure the wires are not live. Do not trust just the switch to stop the power. Tell others in your home that you are working on the electrical system. Put a note on the breaker box to remind everyone. Doing this can help stop accidents and injuries when you install a light switch.

Personal Protection

Wear the right personal protection equipment (PPE) when working with electricity. Electrical dangers can cause shocks, burns, or even arc flashes. Even a small current, like 5 milliamps, can hurt you if it goes through your body. In 2020, 126 workers died from electrical exposure. You can lower your risk by wearing insulated gloves, safety glasses, and special shoes. The National Fire Protection Association (NFPA 70E) says you need PPE for any system over 50 volts. PPE is still important for low-voltage jobs like wiring a light switch. Wire harness testers and wire crimping machines help you avoid mistakes, but PPE gives you extra safety.

Tip: Always check your PPE for damage before you use it. Replace anything that is worn or torn right away.

Code Compliance

You must follow local, state, and national electrical codes for every job. These rules keep your home safe and help stop fires. Inspectors look at your work to make sure you follow the rules. Use wires with the right insulation and put in protective devices like circuit breakers. Good cable management, like using trays and ties, keeps your setup neat and safe. Do not overload circuits or strip wires the wrong way. If you are not sure, check the manual or ask for help. Suzhou Crown gives guides and after-sales help for their products, making it easier to follow electrical codes for wiring.

How to Wire a Light Switch

![How to Wire a Light Switch]()

Wiring a single-pole light switch is easier and safer with wire processing machines. You can follow simple steps to get good results every time. This guide will show you how to wire a light switch using modern tools. You will save time and make fewer mistakes.

Preparing Wires

First, gather all the wires you need for your project. Find the line, load, and ground wires. The line wire brings power from the breaker. The load wire sends power to the light. The ground wire keeps the system safe. Use color codes to tell the wires apart. Black or red is for line, white is for load, and green or bare is for ground.

Wire processing machines help you get ready faster than doing it by hand. When you use the same steps each time, you can work faster and better. This way, you avoid mistakes and keep your work neat.

Tip: Always check wire labels before you start. Automated marking systems help you find wires faster and make your job easier.

Cutting and Stripping

Use a wire cutting and stripping machine to cut wires to the right length. Set the machine for the size of wire you have. The machine will take off just enough insulation for a clean end. This is important for safety and good connections.

Cutting and stripping wires with machines saves time and money. You also do not hurt the wire like you might if you do it by hand. Machines from Suzhou Crown can handle many wires at once. This is good for small jobs at home or bigger projects.

Crimping and Connecting

After stripping the wires, use a wire crimping machine to add terminals or connectors. Put the wire and terminal in the machine and press the button. The machine makes a tight crimp. Real-time monitoring checks the pressure and makes sure the crimp is right.

Real-time monitoring helps every crimp turn out well.

Quick changes fix problems and make your work better.

You get strong and steady connections, which is important for wiring switches.

Performance Aspect | Description and Benefits |

Consistency and Reliability | Crimped connections are more steady and reliable than soldering. |

Heat and Vibration Resistance | Crimped connections stand up to heat and shaking, so wires last longer. |

Safety Improvements | Good crimps lower the chance of shorts, shocks, and fires. |

Electrical Conductivity | Good crimping means less energy is lost and switches work better. |

Always pull on the wire after crimping to make sure it is tight. Using the right tools and steps helps your single-pole light switch work safely and last longer.

Note: Suzhou Crown gives you manuals and videos with each machine. If you have questions, their support team can help you fix any wiring problems.

Grounding

Grounding is very important when you wire a light switch. Connect the ground wire (green or bare) to the switch’s ground terminal. Use a wire nut or crimp connector to make it tight. Do not use electrical tape instead.

Good grounding lets extra electricity go safely into the earth. This stops shocks and lowers fire risks.

Grounding keeps voltage steady and protects your lights and appliances from surges.

All grounding parts—like electrodes, conductors, and connectors—must work together for safety.

Without grounding, you could get shocked, start a fire, or break your electrical system.

Only use approved connectors to keep the ground connection strong.

If you are not sure, ask an electrician or use a wire harness tester to check your work.

Alert: Always check grounding with a multimeter or circuit tester before you finish the switch.

Switch Installation

Now you can install the single-pole light switch. Attach the line, load, and ground wires to the right spots on the switch. Tighten the screws so the wires do not come loose. Gently fold the wires into the box and put the switch in place. Add the cover plate.

Test your switch before you close everything up. Use a wire harness tester to make sure the connections are right. Automated testing tools help you find problems before they cause danger.

Using wire processing machines for each step can save you a lot of time. Ergonomic workstations and mobile wire processing stations help you work faster and feel less tired. Suzhou Crown’s guides and support make sure you always have help when you need it.

Tip: For more about wire processing machines, wire crimping machines, and wire harness testers, visit Suzhou Crown’s product page. These tools help you wire switches safely, quickly, and well every time.

Install a New Single-Pole Switch

Removing Old Switch

You need to remove the old switch before you can install a light switch. Start by turning off the power at the main circuit breaker. Always check the switch with a voltage tester to make sure the circuit is dead. Safety comes first.

Follow these steps to remove the old switch:

Unscrew the switch plate and set it aside.

Use a voltage tester again to confirm no power flows to the switch.

Unscrew the switch from the electrical box and gently pull it out.

Label each wire with masking tape and a marker. This helps you remember where each wire goes.

Remove wires one at a time. Take a picture or use a wiring diagram for reference.

Loosen the screws on the side of the switch. If wires are in the back-wire holes, insert a small screwdriver into the slot under the hole and pull the wire loose.

Avoid using back-stabbing connections. Always use screw terminals for better reliability.

Tip: Work on one switch at a time. This keeps wires organized and prevents confusion.

Wiring the New Switch

Now you can start wiring the new single-pole switch. Identify the wire types: black (hot) connects to the brass screw, white (neutral) connects to the silver screw, and green or bare copper (ground) connects to the green screw or the electrical box.

Use a wire cutting and stripping machine to prepare the wire ends. Strip about 1/2 inch of insulation from each wire. A wire crimping machine helps you attach terminals for a secure fit. Loop each wire clockwise around the terminal screw and tighten it. This method gives you a strong connection and helps prevent loose wires.

Note: Using wire processing machines ensures every connection is neat and consistent. This step is important for safe and reliable wiring.

Securing and Testing

After wiring, gently push the switch back into the box. Screw it in place and attach the switch plate. Restore power at the breaker. Test the switch to make sure it works. If the light does not turn on, check your connections. A wire harness tester can help you find wiring problems quickly.

Step | What to Do |

Secure the switch | Push switch into box and screw it in place |

Attach plate | Screw on the switch plate |

Restore power | Turn breaker back on |

Test the switch | Flip switch and check if light works |

Troubleshoot | Use wire harness tester if switch does not work |

Alert: If you have trouble, check your wiring diagram or ask for technical support. Suzhou Crown offers installation guidance and after-sales service for all wire processing machines.

Using the right tools, like wire cutting and stripping machines, helps you install a light switch safely and efficiently. You get reliable results every time.

Efficiency Tips

Best Practices

You can wire a switch faster and safer by following a few best practices. Always organize your workspace before you start. Lay out your wire harness tester, wire crimping machine, and all tools you need. Double-check the wiring diagram for your switch. Use a wire processing machine to cut and strip wires to the right length. This step keeps every switch connection neat and secure. Label each wire as you go. When you connect wires to the switch, make sure each terminal is tight. Test every switch with a wire harness tester before you finish the job.

Tip: Keep your tools clean and ready. This habit helps you avoid mistakes when wiring a switch.

Maintenance

Regular maintenance keeps your wire processing machines working well. If you skip maintenance, your switch wiring projects may slow down or fail. You should follow a schedule for cleaning and checking your machines. Here are some important tasks:

Clean the wire threading system and rollers every week.

Check the alignment of wire guides before each switch project.

Replace filters and belts every few months.

Lubricate moving parts to prevent wear.

Empty the wire collection box often.

If you keep up with these tasks, your machines will last longer and your switch installations will stay reliable. Preventive maintenance also helps you avoid costly repairs and downtime.

Troubleshooting

Sometimes, you may face problems when wiring a switch. If a switch does not work, check your connections first. Use a wire harness tester to find any loose or broken wires. Look for signs of wear on your wire crimping machine. If you see uneven crimps, clean or replace the tool. Always check the user manual for your wire processing machine. Suzhou Crown offers after-sales support if you need extra help. You can also watch installation videos for step-by-step guidance.

Problem | What to Check | Solution |

Switch not working | Wire connections, power supply | Retighten or reconnect wires |

Loose switch terminals | Crimp quality, terminal screws | Re-crimp or tighten screws |

Machine error | Maintenance schedule, error codes | Clean, reset, or call support |

Note: Quick troubleshooting keeps your switch projects on track and helps you deliver high-quality results every time.

Wire processing machines help you wire switches quickly and safely. They make sure wires are cut neatly and connected well. A wire crimping machine and wire harness tester help you meet safety rules. Always follow safety steps when you put in a switch. If your project is hard, Suzhou Crown can help with advice and good tools. Pick the best tools for each switch job. You can find more tips and great switch tools at Suzhou Crown. This helps you install switches that are safe, fast, and look professional.

FAQ

How do wire processing machines make wiring a light switch easier?

Wire processing machines cut, strip, and crimp wires quickly. You get clean, accurate results every time. These machines help you avoid mistakes and save time. You can use them for both home and commercial wiring projects.

What is the best wire crimping machine for home wiring?

You should choose a wire crimping machine that matches your wire size and project needs. Look for machines with adjustable settings. Suzhou Crown offers several options for home and professional use. You can find more details on their product page.

Do I need a wire harness tester when wiring a light switch?

Yes, you should use a wire harness tester. This tool checks your connections for safety and accuracy. It helps you find problems before you finish the job. You can trust your light switch will work correctly.

Can I label wires automatically for better organization?

You can use an automatic wire labeling machine. This tool prints and attaches labels to wires. Labeled wires help you stay organized and make future repairs easier. You can find these machines on Suzhou Crown’s website(www.autowireprocessing.com).